Your trusted Hopcalite Catalysts And Ozone Destruction Catalyst Manufacturer

Specialized focus on manufacturing high-quality Hopcalite catalyst and Ozone Destruction Catalyst

Over 10 Years in Manufacturing Hopcalite Catalyst and Ozone Destruction Catalyst

Welcome to HiChemi, a leader in the field of Hopcalite Catalyst and Ozone Destruction Catalyst technology with a specialized focus on manufacturing high-quality Hopcalite Catalyst and Ozone Destruction Catalyst. With decades of experience and a commitment to excellence, we have established ourselves as a trusted provider of catalytic solutions for a wide range of applications.

Why Choose Our Hopcalite Catalyst and Ozone Destruction Catalyst?

Superior Quality and Performance

High Efficiency

Our Hopcalite Catalyst and Ozone Destruction Catalyst are engineered for maximum efficiency in the catalytic oxidation of carbon monoxide (CO), ozone(O3) and other harmful gases. This ensures rapid and effective purification of air in various environments.

Robust Composition

Made from a meticulously optimized blend of manganese dioxide and copper oxide, our catalysts exhibit excellent stability and long-lasting performance under diverse operating conditions.

Proven Reliability

With extensive testing and field validation, our Hopcalite catalysts have consistently demonstrated their reliability in real-world applications, providing peace of mind for our customers.

Advanced Manufacturing and Quality Control

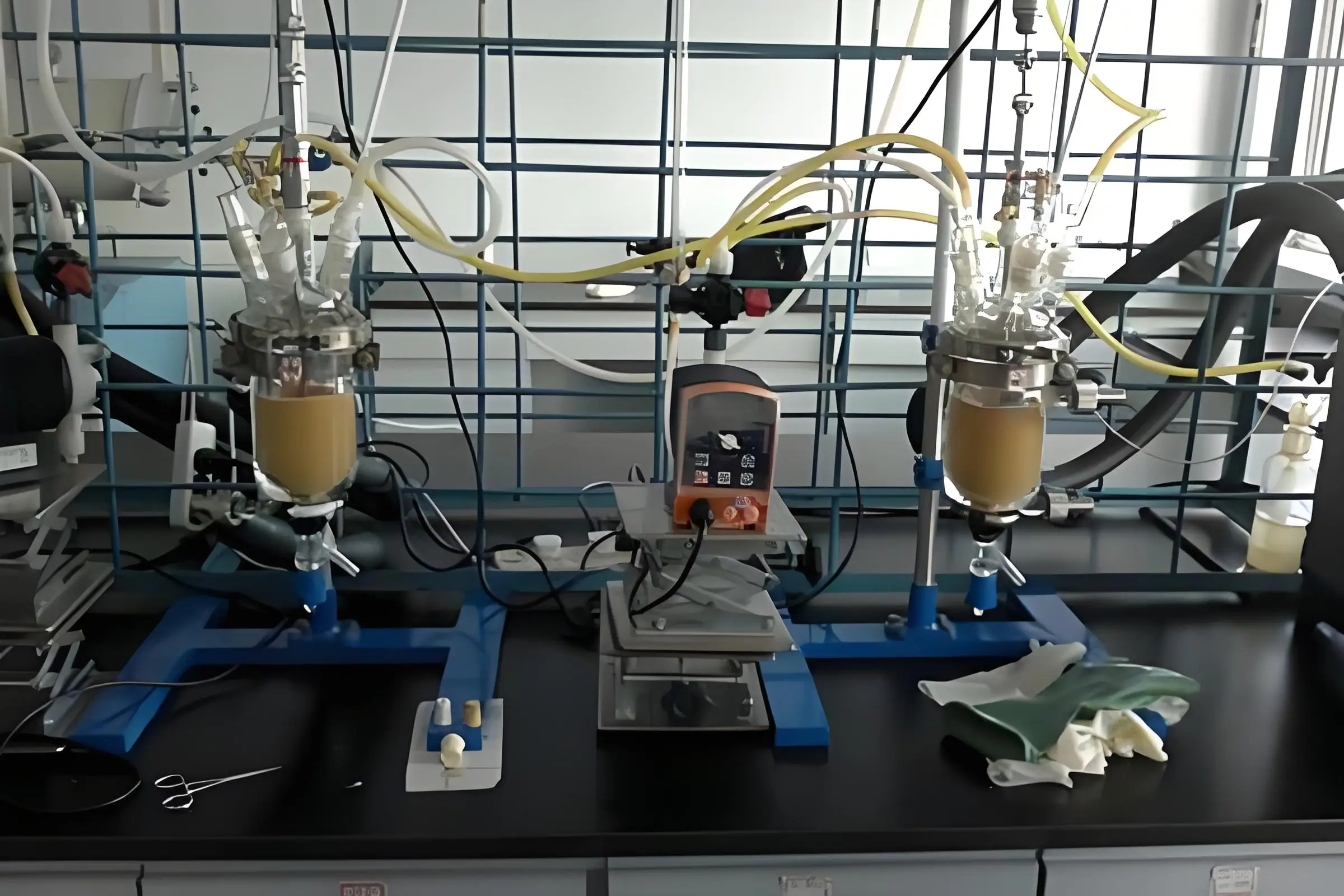

State-of-the-Art Production

Utilizing the latest manufacturing technologies, our production process ensures that each catalyst batch meets the highest standards of quality and consistency.

Stringent Quality Assurance

Every batch undergoes rigorous quality control procedures, including chemical composition analysis, performance testing, and durability assessments, to guarantee top-tier products.

Exceptional Customer Support

Expert Guidance

Our knowledgeable technical support team is always ready to assist you with product selection, application advice, and troubleshooting, ensuring you get the most out of our catalysts.

Comprehensive Support

From the initial consultation through to after-sales service, we provide comprehensive support to ensure your complete satisfaction. Our goal is to build long-term partnerships based on trust and mutual success.

Advantages in Hopcalite Catalyst and Ozone Destruction Catalyst Manufacturing

Advanced Manufacturing Techniques

We employ cutting-edge manufacturing techniques to ensure that our Hopcalite Catalyst and Ozone Destruction Catalyst exhibit optimal performance and durability. Our production facilities are equipped with modern machinery and operated by skilled professionals who are dedicated to maintaining quality at every step

Research and Development

Innovation is the cornerstone of our approach. Our R&D department is constantly exploring new formulations and methods to enhance the efficacy of our catalysts. By staying at the forefront of technological advancements, we are able to offer products that not only meet but exceed customer expectations.

Continuous R&D

Our dedicated research and development team is constantly exploring new materials and processes to enhance the effectiveness of our Hopcalite Catalyst and Ozone Destruction Catalyst. This commitment to innovation keeps us at the forefront of catalyst technology.

Applications of Hopcalite Catalyst and Ozone Destruction Catalyst

Hopcalite Catalyst and Ozone Destruction Catalyst are versatile and essential in numerous industries and scenarios where the control and reduction of carbon monoxide and ozone and other harmful gases are critical. Their application ranges from industrial safety and environmental protection to consumer products and cutting-edge research, demonstrating their vital role in promoting health, safety, and sustainability across various sectors.

Ozone Destruction Catalyst are used in waste incineration plants to treat flue gases, reducing the emission of ozone and ensuring compliance with environmental regulations. Applicable to ozone tail gas destruction devices in sewage treatment plants. When sewage treatment plants use ozone for ozone oxidation disinfection, the excess tail gas will be decomposed into non-toxic oxygen through the ozone decomposition catalyst in the tail gas destruction device.

Air compressors are widely used in various industrial applications, including manufacturing, automotive, and healthcare. The quality of compressed air is crucial, as contaminants like carbon monoxide can pose significant risks to both equipment and personnel. Hopcalite catalysts, renowned for their ability to catalyze the oxidation of carbon monoxide (CO) and other harmful gases, play a critical role in the air compressor industry.

In both fossil fuel and biomass power plants, CO emissions can be significant. Hopcalite catalysts help in the effective conversion of CO to CO2, minimizing environmental impact and complying with regulatory standards.

Chemical Production

Chemical plants often generate various gases, including CO. Hopcalite catalysts are used to treat emissions, preventing the release of harmful pollutants into the atmosphere.

Gas Masks and Respirators

Personal protective equipment (PPE) like gas masks and respirators incorporate Hopcalite catalysts to protect individuals from inhaling CO and other toxic gases, crucial for firefighters, industrial workers, and military personnel.

Emergency Escape Devices

Devices designed for emergency evacuations in environments where CO exposure is a risk utilize Hopcalite catalysts to ensure safe breathing during escape.

Laboratory Applications

Research institutions and laboratories use Hopcalite catalysts in various experimental setups to study the catalytic oxidation of CO and develop new air purification technologies.

Hopcalite Catalysts Case Studies

Waste Treatment Facilities

Air compressor

Contact Us

F.A.Q.

Yes, of course. We are a technology company specializing in the treatment of waste gases including ozone and carbon monoxide. Please contact us and let us know your question.

Yes, our ozone destruction catalysts are particularly effective for tail gas destruction devices in wastewater treatment plants. Please contact us for sample testing!

Yes, of course, we understand the importance of sample testing, contact us and tell us your information. Then our professional technical team will calculate and select the appropriate catalyst sample for testing

Yes, of course, we have a professional technical team to serve you. You can contact us for technical support at any time

If stored in an airtight container, it generally lasts 2 to 3 years.

Our catalysts are very effective and can reduce the concentrations of ozone and carbon monoxide to levels that are not harmful to humans.

Our catalysts are calculated by weight, and the specific price information needs to be evaluated according to your project situation. Contact us to get your detailed quotation information

We support express delivery, air transportation, sea transportation, etc.